Categories: Inventory Management

By Mark Tomalonis

Principal, WarehouseTWO, LLC

I am surprised by how often I get an auto-response email from one of our wholesaler-distributor clients that states, “We are closed today for our annual physical inventory count.” Wow. Why would a distributor be closed on a normal business day? Its competitors are not closed on that day. More importantly, its customers are not closed on that day.

I am surprised by how often I get an auto-response email from one of our wholesaler-distributor clients that states, “We are closed today for our annual physical inventory count.” Wow. Why would a distributor be closed on a normal business day? Its competitors are not closed on that day. More importantly, its customers are not closed on that day.

This got me thinking. Why do some distributors still perform annual “wall-to-wall” physical counts of all on-hand inventory instead of “cycle-counts”, i.e., scheduled physical counts of a portion of on-hand inventory every week, throughout the year? The only reasons that I can think of are, “tradition” and “fear of change”. So, to you traditionalists (and scaredy-cats) out there, here are four reasons why cycle-counting a portion of your inventory every week, throughout the year, is better for your company than an annual physical inventory count.

This got me thinking. Why do some distributors still perform annual “wall-to-wall” physical counts of all on-hand inventory instead of “cycle-counts”, i.e., scheduled physical counts of a portion of on-hand inventory every week, throughout the year? The only reasons that I can think of are, “tradition” and “fear of change”. So, to you traditionalists (and scaredy-cats) out there, here are four reasons why cycle-counting a portion of your inventory every week, throughout the year, is better for your company than an annual physical inventory count.

Reason #1: You will never have to tell your customers that you are "Closed for Inventory". 'nuff said.

Reason #2: Cycle-counting is less expensive than an annual physical inventory count. Compare labor costs. Cycle-counting is done by warehouse staff, usually one of the lower paid positions in your company. Cycle-counting is done during normal business hours. No overtime. Annual physical inventory counts are commonly done by other, more highly paid employees in addition to warehouse staff, and often at overtime rates, particularly if done after hours or on a weekend. Even if you count a portion of your items more frequently than once per year (which is typical in a cycle-count program), your annual costs are still lower with cycle-counting.

Reason #2: Cycle-counting is less expensive than an annual physical inventory count. Compare labor costs. Cycle-counting is done by warehouse staff, usually one of the lower paid positions in your company. Cycle-counting is done during normal business hours. No overtime. Annual physical inventory counts are commonly done by other, more highly paid employees in addition to warehouse staff, and often at overtime rates, particularly if done after hours or on a weekend. Even if you count a portion of your items more frequently than once per year (which is typical in a cycle-count program), your annual costs are still lower with cycle-counting.

Reason #3: With cycle-counting, your inventory will be more accurate throughout the year. Two factors contribute to this:

Reason #3: With cycle-counting, your inventory will be more accurate throughout the year. Two factors contribute to this:

Factor #1: The quality of work done during cycle counts is higher than the quality of work done during an annual physical inventory count. Which of these groups of employees would you rather determine the accuracy of your inventory, one of your largest assets?

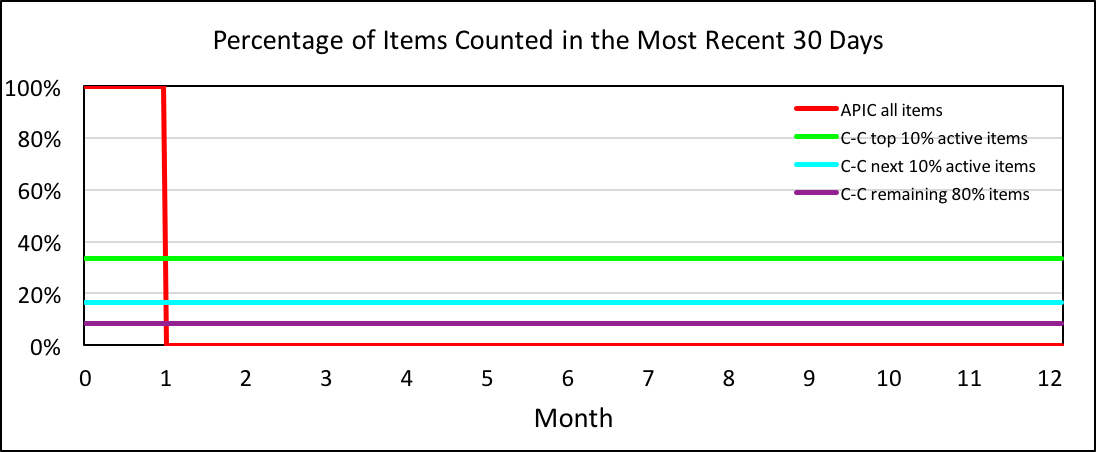

Factor #2: With cycle-counting, more items will have been counted more recently throughout the year. That is, the counts will be “fresher” than with an annual physical inventory count. “Freshness” translates to “accuracy”. Consider these two scenarios:

Comparing these two scenarios, the average “freshness” (how recently an item was physically counted) of your inventory is higher throughout the year under a cycle-counting program than it is under an annual physical inventory count program. Particularly for your most active items. The chart below illustrates this phenomenon. In this chart, a higher trend line means “fresher” inventory counts, which translates into greater inventory accuracy. (APIC= “annual physical inventory count”; C-C= “cycle-counted”.) The point here is that, with an annual physical inventory count, after 30 days, none of your items have been counted in the last 30 days. But with a properly designed cycle-count program, 33% of your most active items will have been counted in the most recent 30 days, 17% of your next most active items will have been counted in the most recent 30 days and 8% of your slowest moving items will have been counted in the most recent 30 days.

Reason #4: With cycle-counting resulting in more accurate inventory throughout the year, particularly for your most active items, unintended “stock-outs” will be reduced. Fewer “stock-outs” means less time and money spent resolving them. What happens when you sell an item from stock, only to discover that the item is not in stock when the order is being picked? First, you panic. Then you scramble. Then you expedite. To avoid disappointing your customer, you might pay a premium to get replacement inventory, plus pay extra for speedier delivery. “Stock-outs” cost time and money. Fewer of them saves time and money.

Reason #4: With cycle-counting resulting in more accurate inventory throughout the year, particularly for your most active items, unintended “stock-outs” will be reduced. Fewer “stock-outs” means less time and money spent resolving them. What happens when you sell an item from stock, only to discover that the item is not in stock when the order is being picked? First, you panic. Then you scramble. Then you expedite. To avoid disappointing your customer, you might pay a premium to get replacement inventory, plus pay extra for speedier delivery. “Stock-outs” cost time and money. Fewer of them saves time and money.

I have not explained here how to set up a sustainable cycle-count program. (Perhaps in a future article.) For now, accept that setting up such a program is not that hard, and that the benefits are well worth the effort. There are many qualified distribution consultants that can help you. Or, contact me via email. In a brief conversation, I can suggest how to get started. The first two questions I will ask you are:

I will have a few (dozen) more questions after those first two. :-)

Compared to annual physical inventory counts, an effective cycle-count program costs less, saves time, and improves overall customer satisfaction. What is not to like?

About the Author After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

About WarehouseTWO

WarehouseTWO, LLC is an independent “inventory-sharing” service created exclusively for durable goods manufacturers and their authorized distributors, and for any group of durable goods “peer” wholesaler-distributors, such as members of a buying/marketing group or cooperative. To learn how inventory-sharing with WarehouseTWO can help your business, visit the WarehouseTWO website, or email info@warehousetwo.com.