Categories: Customer Service, Inventory Management

By Mark Tomalonis

Principal, WarehouseTWO, LLC

Are you a stocking wholesaler-distributor (“distributor”) who sells branded products from selected manufacturer partners (“suppliers”)? And have you recently taken on a new supplier? Congratulations! More products to sell. New customers to sell to. All good.

Are you a stocking wholesaler-distributor (“distributor”) who sells branded products from selected manufacturer partners (“suppliers”)? And have you recently taken on a new supplier? Congratulations! More products to sell. New customers to sell to. All good.

Of course, your new supplier immediately expects your company to do these two things:

I will let sales strategists provide advice on the first expectation, “sell its products”.

About that “stock its products” expectation: what should you stock? Usually, a distributor stocks items based on past history, contractual obligations, or informed forecasts. But, when taking on a new supplier, none of this information may be available to you. Or it may be inaccurate or untrustworthy. In the absence of reliable information, you may be left with guessing, or with relying on the new supplier’s recommendation. (I am often impressed by how confident a supplier’s stock position recommendation is… when it is your money that pays for the new stock.)

When placing an initial stocking order with a new supplier, clearly understand what you are doing: you are converting risk-free, totally liquid cash into a risky, nonliquid, speculative asset.

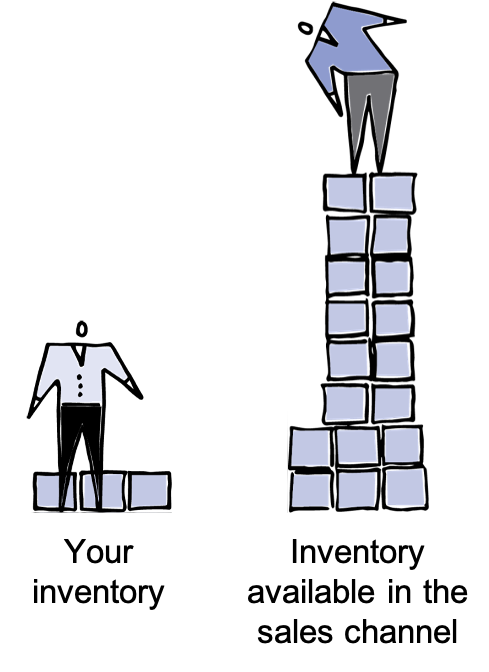

Before you make such an investment in speculative inventory, do this one thing first: identify, and then leverage, what inventory is available from other distributors who already sell this supplier’s products. You can do this with “inventory-sharing” (or “inventory-pooling”). This is the practice of a manufacturer and its channel partners (i.e., its distributors) populating a common database with information about finished goods inventory available in the channel. The benefit of “inventory-sharing” is that all participants have access to more finished goods inventory than any one distributor would ever want to own.

The benefit of “inventory-sharing” as a you begin your partnership with a new supplier is that you can reduce the risk of investing in speculative inventory. At first, put into stock only the highest velocity, most commonly sold items (based on the supplier’s recommendation), and then leverage the inventories available from peer distributors to fulfill the demand for a broader range of less commonly sold, riskier-to-own items. That is, treat this new supplier’s sales channel partners as alternate sources for this supplier’s products, for quick delivery to your end-customers. Sure, your profit will be less when buying from another distributor. But during the first year of your partnership with a new supplier, your priority should be end-customer satisfaction over profit on rarely sold, non-stock items. Only after many months of actual sales history should you consider increasing the breadth of your stocking position of this new supplier’s products.

The benefit of “inventory-sharing” as a you begin your partnership with a new supplier is that you can reduce the risk of investing in speculative inventory. At first, put into stock only the highest velocity, most commonly sold items (based on the supplier’s recommendation), and then leverage the inventories available from peer distributors to fulfill the demand for a broader range of less commonly sold, riskier-to-own items. That is, treat this new supplier’s sales channel partners as alternate sources for this supplier’s products, for quick delivery to your end-customers. Sure, your profit will be less when buying from another distributor. But during the first year of your partnership with a new supplier, your priority should be end-customer satisfaction over profit on rarely sold, non-stock items. Only after many months of actual sales history should you consider increasing the breadth of your stocking position of this new supplier’s products.

What? This new supplier’s other distributors do not already have an active “inventory sharing” system? No worries. Setting one up is easy. And fun! Ask me how.

Have you read this far? Excellent. Here’s a bonus tip: the second thing you should do after partnering with a new supplier, and before placing a speculative stock order, is to negotiate with the supplier a favorable inventory exchange agreement executable six months to one year after placing your initial stock order.

Incidentally, one of your existing suppliers introducing a new product line is very similar to taking on a new supplier. Before making a speculative investment in inventory of a new product line, collaborate with peer distributors to mitigate the risk of owning more speculative inventory, through “inventory-sharing”. Click here for more tips on what to do when a supplier introduces a new product line (or kills an old one).

About the Author After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

About WarehouseTWO

WarehouseTWO, LLC is an independent “inventory-sharing” service created exclusively for durable goods manufacturers and their authorized distributors, and for any group of durable goods “peer” wholesaler-distributors, such as members of a buying/marketing group or cooperative. To learn how inventory-sharing with WarehouseTWO can help your business, visit the WarehouseTWO website, or email info@warehousetwo.com.