Categories: Inventory Management

By Mark Tomalonis

Principal, WarehouseTWO, LLC

As the graphic to the right suggests, inventory management is a balancing act between two opposing goals: "asset efficiency" (having less inventory) and "transaction efficiency" (having more inventory).

As the graphic to the right suggests, inventory management is a balancing act between two opposing goals: "asset efficiency" (having less inventory) and "transaction efficiency" (having more inventory).

How do you explain to your employees the decision process behind inventory management? How do you explain it to your sales team?

An employee with a basic understanding of inventory management should be able to answer these three questions:

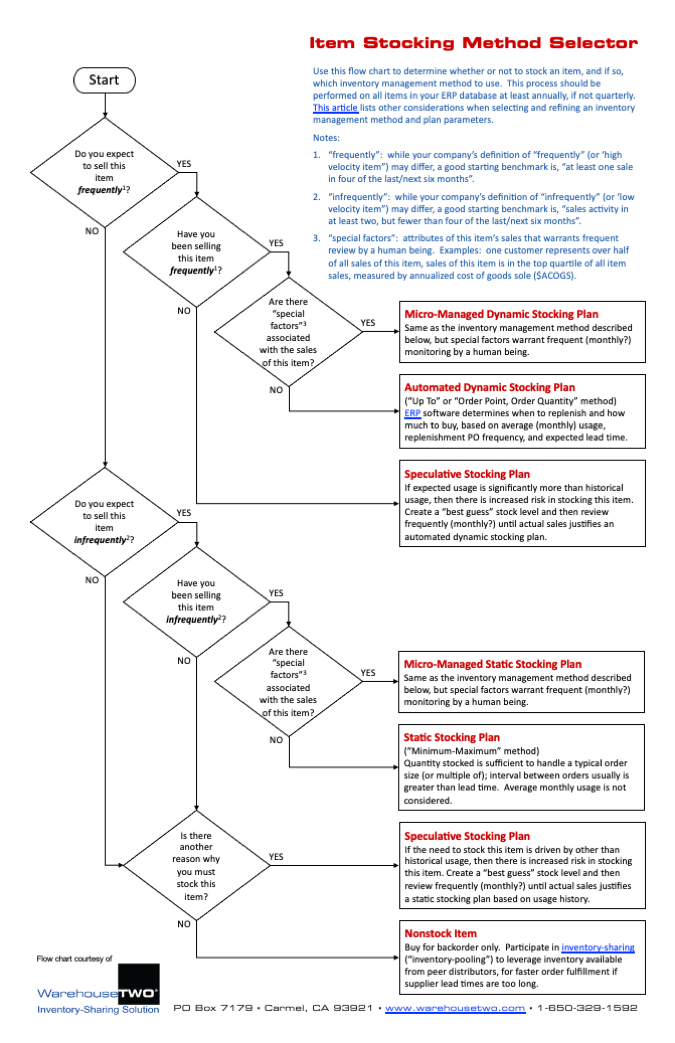

To assist in training your employees, the flow chart below distills inventory management down to a series of questions and possible outcomes. (Click here to download a large PDF version.)

This flow chart shows that there are five basic types of inventory management methods:

Of course, the above flow chart does not account for all factors that influence whether to stock an item or how to manage an inventoried item. Other considerations include:

I bet that you, the reader, can add to this list of considerations.

Inventory management has a significant effect on customer satisfaction and your company’s financial performance. And it is a complex discipline. This is why people get degrees or certifications on the subject, why there are professional consultants available to share their expertise, and why your company has (or should have) a modern ERP system to help automate many of the decisions and actions relating to inventory management. Also, it is why your inventory manager should be the smartest person in the room.

Got a question or comment about this article? Email me.

About the Author After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help manufacturers and wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help manufacturers and wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

About WarehouseTWO

WarehouseTWO, LLC is an independent “inventory-pooling” service created exclusively for durable goods manufacturers and their authorized distributors, and for any group of durable goods “peer” wholesaler-distributors, such as members of a buying/marketing group or cooperative. To learn how inventory-pooling with WarehouseTWO can help your business, visit the WarehouseTWO website, or email info@warehousetwo.com.