Categories: Customer Service, Inventory Management

By Mark Tomalonis

Principal, WarehouseTWO, LLC

If you are a manufacturer of engineered products, it is likely that some of your products, or at least some components of your assembled products, are machined, molded or otherwise fabricated by specialized equipment. Once that equipment has been set up to make one piece, the more pieces you make, the lower the cost of each one that you make. But too often, your sales channel partners (i.e., stocking distributors) want only one or two pieces.

If you are a manufacturer of engineered products, it is likely that some of your products, or at least some components of your assembled products, are machined, molded or otherwise fabricated by specialized equipment. Once that equipment has been set up to make one piece, the more pieces you make, the lower the cost of each one that you make. But too often, your sales channel partners (i.e., stocking distributors) want only one or two pieces.

This article discusses the cost of a small-volume production runs and how smart manufacturers and their sales channel partners take a holistic approach to reducing the frequency of low-volume production runs.

Setting up specialized equipment to make the first piece of a production run incurs these costs (among others?):

What do these costs amount to? According to the internet (and I believe everything I see on the internet), the cost of creating the first piece in a manufacturing run is:

C = Tf(x) + rp(xT-QT)/2 + SQ/xT

To me, that looks a lot like "$500". If you include overhead, maintenance costs and lost opportunity costs, then any sale of less than $2000 from a single production run is probably unprofitable. (Your mileage may vary.)

Other than refusing the order without an alternative method of fulfilling the demand, consider these two methods to reduce the frequency of low-volume, unprofitable manufacturing product runs.

From personal experience, I believe that the most commonly used methods by manufacturers to reduce the frequency of low-volume production orders are by policies imposed on their sales channel partners. Three common policies:

From personal experience, I believe that the most commonly used methods by manufacturers to reduce the frequency of low-volume production orders are by policies imposed on their sales channel partners. Three common policies:

I refer to these as “poke-in-the-eye” policies.

While these policies are effective in changing a sales channel partner's purchasing practices, they also result in those partners owning more inventory than they need. That means money and warehouse space committed to non-moving inventory in the sales channel. That is painful, like a poke in the eye. Not good for anyone.

And while purchase order policies can reduce low-volume production runs, the sales channel is still going to demand small quantities of some items.

There is a better way to efficiently reduce small volume product runs, while filling the demands of sales channel partners for small quantities of an item.

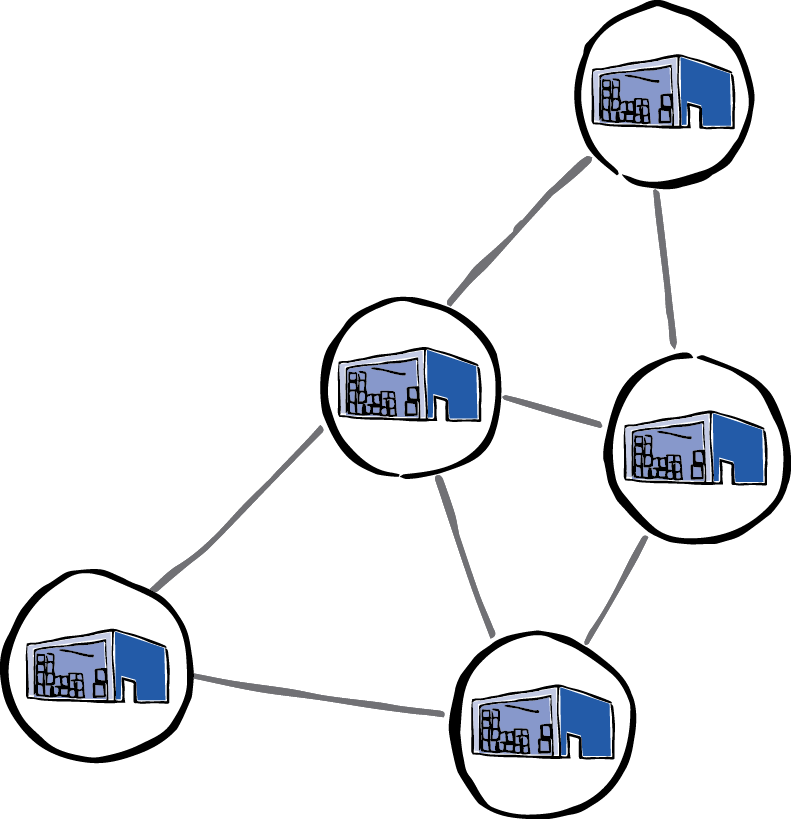

To avoid low-volume production runs without inflicting pain on its sales channel partners, smart manufacturers take a more holistic approach: collaborate with sales channels in the practice of "inventory-pooling". Via "inventory-pooling", all sales channel partners have access to all of the finished goods inventory available in the sales channel. Think of "inventory-pooling" as an inter-connected network of independently owned stocking locations that create one big "virtual" pile of inventory, accessible by all sales channel partners. The benefit of "inventory-pooling" for manufacturers is that small quantity demands by one channel partner can be fulfilled by another channel partner who has that small quantity in stock, available for immediate shipment.

To avoid low-volume production runs without inflicting pain on its sales channel partners, smart manufacturers take a more holistic approach: collaborate with sales channels in the practice of "inventory-pooling". Via "inventory-pooling", all sales channel partners have access to all of the finished goods inventory available in the sales channel. Think of "inventory-pooling" as an inter-connected network of independently owned stocking locations that create one big "virtual" pile of inventory, accessible by all sales channel partners. The benefit of "inventory-pooling" for manufacturers is that small quantity demands by one channel partner can be fulfilled by another channel partner who has that small quantity in stock, available for immediate shipment.

Key elements of "inventory-pooling":

With "inventory-pooling", all parties effected by the practice win:

That is four “wins”. What other type of collaboration between a manufacturer and its sales channel partners has such instant benefits for so many parties?

Deploying "inventory-pooling" is easy. And fun! Ask me how.

About the Author After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help manufacturers and wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help manufacturers and wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

About WarehouseTWO

WarehouseTWO, LLC is an independent “inventory-pooling” service created exclusively for durable goods manufacturers and their authorized distributors, and for any group of durable goods “peer” wholesaler-distributors, such as members of a buying/marketing group or cooperative. To learn how inventory-pooling with WarehouseTWO can help your business, visit the WarehouseTWO website, or email info@warehousetwo.com.