Categories: Inventory Management

By Kathy Tomalonis

Principal, WarehouseTWO, LLC

February 2016

For many wholesalers, 2015 did not end on an upswing in business, and 2016 has not started out so well either. Lower-than-expected sales often triggers difficult realities, including reduction in resources (i.e., layoff of employees) and shrinking cash reserves.

For many wholesalers, 2015 did not end on an upswing in business, and 2016 has not started out so well either. Lower-than-expected sales often triggers difficult realities, including reduction in resources (i.e., layoff of employees) and shrinking cash reserves.

Formalized “inventory-sharing” is the practice of peer wholesalers (usually representing a specific manufacturer’s network of authorized sales/fulfillment partners) easily browsing each other’s inventories. Here is how “inventory-sharing” can help a wholesaler’s business during challenging times…

Your Challenge: Lower Sales

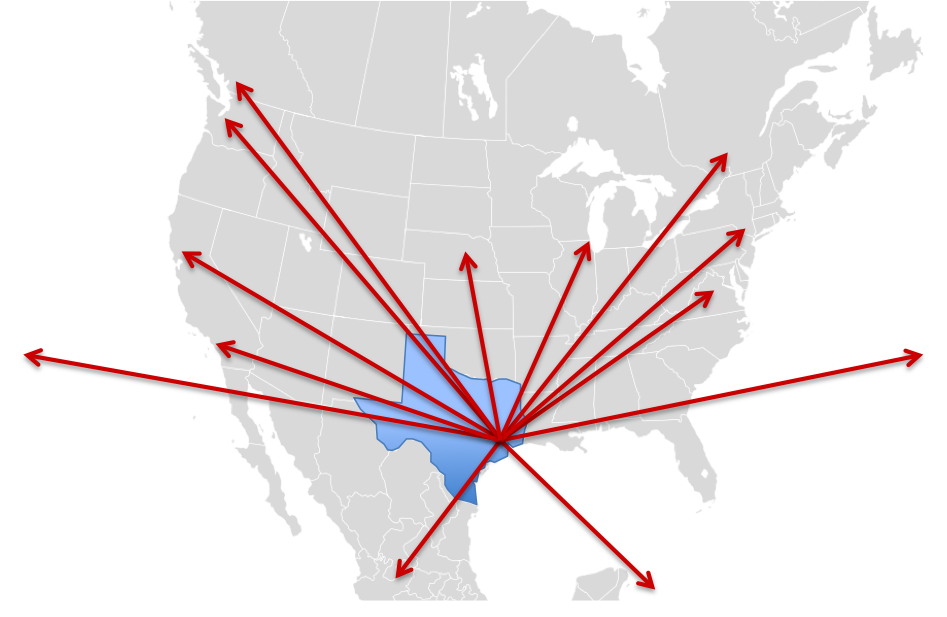

How “inventory-sharing” can help: “Inventory-sharing” effectively increases your sales territory. If you are a regional wholesaler, your geographical reach for customers is limited by your available resources (e.g., field sales staff) or by your agreements with your suppliers. In either case, you are denied access to tens of thousands of potential end-customers who may want to buy what you have in stock today. By offering your inventory to peer wholesalers located outside of your traditional sales territory, you can expose your inventory to those tens of thousands of potential end-customers in other parts of the country… or in the rest of the world. Greater exposure of your inventory to an active inventory-sharing network can result in more sales, without adding additional sales resources or paying out additional sales commissions. And because any order that you might get from a peer wholesaler is for an in-stock item, your cost of the transaction is very low: just pick, pack and ship.

How “inventory-sharing” can help: “Inventory-sharing” effectively increases your sales territory. If you are a regional wholesaler, your geographical reach for customers is limited by your available resources (e.g., field sales staff) or by your agreements with your suppliers. In either case, you are denied access to tens of thousands of potential end-customers who may want to buy what you have in stock today. By offering your inventory to peer wholesalers located outside of your traditional sales territory, you can expose your inventory to those tens of thousands of potential end-customers in other parts of the country… or in the rest of the world. Greater exposure of your inventory to an active inventory-sharing network can result in more sales, without adding additional sales resources or paying out additional sales commissions. And because any order that you might get from a peer wholesaler is for an in-stock item, your cost of the transaction is very low: just pick, pack and ship.

Your Challenge: Fewer Resources How “inventory-sharing” can help: “Inventory-sharing” can reduce order management workload, requiring fewer resources. By sourcing a backordered item from a peer wholesaler who has the item in stock, you can close the backorder faster, with less effort and at lower cost. The longer an open backorder lingers, the more resources are consumed to manage it, such as for expediting and for customer relationship management. Lingering open back orders can consume more cash too, such as for premium inbound freight or for expedited manufacturing fees. By leveraging the inventories available from peer wholesalers, you can turn orders into receivables with minimal effort.

How “inventory-sharing” can help: “Inventory-sharing” can reduce order management workload, requiring fewer resources. By sourcing a backordered item from a peer wholesaler who has the item in stock, you can close the backorder faster, with less effort and at lower cost. The longer an open backorder lingers, the more resources are consumed to manage it, such as for expediting and for customer relationship management. Lingering open back orders can consume more cash too, such as for premium inbound freight or for expedited manufacturing fees. By leveraging the inventories available from peer wholesalers, you can turn orders into receivables with minimal effort.

Your Challenge: Less Cash How “inventory-sharing” can help: “Inventory-sharing” can help convert slow-moving inventory into needed cash. As sales drop, so does gross profit. Unless costs are cut proportionally, cash reserves will decrease. By offering all of your available inventory to peer wholesalers, you will increase your chances of liquidating slow-moving inventory. Because of the nature of slow-moving inventory, you will be unlikely to buy more of it, resulting in a net cash gain.

How “inventory-sharing” can help: “Inventory-sharing” can help convert slow-moving inventory into needed cash. As sales drop, so does gross profit. Unless costs are cut proportionally, cash reserves will decrease. By offering all of your available inventory to peer wholesalers, you will increase your chances of liquidating slow-moving inventory. Because of the nature of slow-moving inventory, you will be unlikely to buy more of it, resulting in a net cash gain.

In summary, formalized “inventory-sharing” among peer wholesalers can have these benefits:

For help with creating a formalized “inventory-sharing” network, contact WarehouseTWO, the leading independent inventory-sharing service for industrial wholesale distributors.

Formalized “inventory-sharing” among a manufacturer’s authorized distributors can help manufacturers too. Read more…

About the Author

Kathleen Tomalonis joined WarehouseTWO, LLC in 2005. She has over twenty years experience in marketing and administrative management. Before joining WarehouseTWO, she spent ten years working in the software industry in Silicon Valley. Kathleen’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

Kathleen Tomalonis joined WarehouseTWO, LLC in 2005. She has over twenty years experience in marketing and administrative management. Before joining WarehouseTWO, she spent ten years working in the software industry in Silicon Valley. Kathleen’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

About WarehouseTWO

WarehouseTWO, LLC is an independent “inventory-sharing” service created exclusively for durable goods manufacturers and their authorized distributors, and for any group of durable goods “peer” wholesaler-distributors, such as members of a buying/marketing group or cooperative. To learn how inventory-sharing with WarehouseTWO can help your business, visit the WarehouseTWO website, or email info@warehousetwo.com.