Is “Inventory-Sharing” a Solution to Your Surplus Inventory Problem? Maybe.

Tuesday, July 9, 2019 8:00:00 AM

Categories:

Inventory Management

By Mark Tomalonis

Principal, WarehouseTWO, LLC

.png) Imagine exponentially increasing the amount and variety of inventory available to your end-customers without increasing the breadth or depth of your own inventory. By pooling each other’s finished goods into one big “virtual” pile of inventory, networks of peer wholesaler-distributors have a much better chance of meeting end-customers’ expectations of 1-to-2 day availability on anything. The practice of formal inventory collaboration among peer wholesaler-distributors is commonly referred to as “inventory-sharing”.

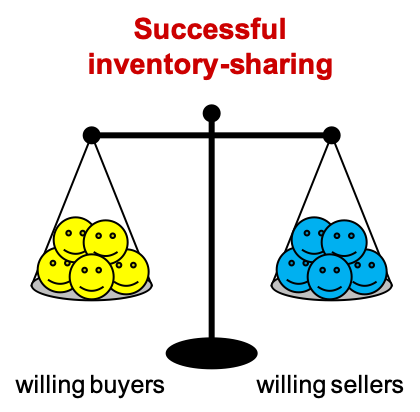

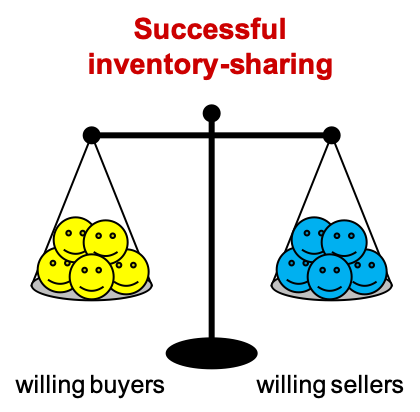

Imagine exponentially increasing the amount and variety of inventory available to your end-customers without increasing the breadth or depth of your own inventory. By pooling each other’s finished goods into one big “virtual” pile of inventory, networks of peer wholesaler-distributors have a much better chance of meeting end-customers’ expectations of 1-to-2 day availability on anything. The practice of formal inventory collaboration among peer wholesaler-distributors is commonly referred to as “inventory-sharing”.

The two most significant benefits of “inventory-sharing” are:

- access to more inventory than one would ever want to own, including low-velocity items for which a local stock plan is not warranted

- expansion of one’s sales territory, by offering one’s available inventory to peer wholesaler-distributors across an expanded geography who in turn are trying to service the product availability needs of their own end-customers

To determine whether or not formalized “inventory-sharing” can help you sell off surplus inventory, first understand what drives successful “inventory-sharing”.

Attributes of Successful “Inventory-Sharing”

In our thirteen years of facilitating “inventory-sharing” networks, we at WarehouseTWO have learned that successful ones have these five attributes in common:

In our thirteen years of facilitating “inventory-sharing” networks, we at WarehouseTWO have learned that successful ones have these five attributes in common:

- Sharing of branded, single-source items. (The source being the manufacturer of the branded items.)

- Sufficient pain in sourcing product from the single-source supplier. The most common cause of sourcing pain is long lead-time availability. Less common causes include restrictive purchase order policies, such as minimum PO value, minimum line item quantities, or full package requirements.

- Sharing of low-cost-to-ship items. Items that can be put in a box or strapped to a pallet and shipped via UPS or FedEx are easily moved between network participants, and the low freight cost can be passed on to the end-customer or absorbed by the buyer.

- Fast rise to “critical mass” participation among network members. The network must quickly attract enough variety of inventory and enough willing buyers to provide a favorable first impression to skeptical participants.

- A network “evangelist”. Every successful network has someone who is accountable for driving participation in “inventory-sharing” among a target group of peer wholesaler-distributors to what we refer to as “critical mass” participation. We have seen that the most effective evangelist is the manufacturer who is inflicting sourcing pain on its wholesale channel partners and genuinely wants to help them work with each other to mitigate its own shortcomings.

In our experience, “inventory-sharing” is less likely to attain “critical mass” participation for these types of products or in these situations:

- Commodities. When a wholesaler-distributor has multiple sources for essentially the same item, there is insufficient pain on the sourcing side to change one’s behavior to seek out a network of peers.

- Perishables. Short shelf-lives reduce the variety of uncommon, low-velocity items available to the network.

- Low value, high cost-to-ship items. If it costs multiples more to ship than the item is worth, buyers will find an alternative solution instead of paying the freight cost.

- Rudderless network. Without an “evangelist”, the network rarely reaches “critical mass” participation.

How “Inventory-Sharing” Can Help You Sell Off Surplus Inventory

How “Inventory-Sharing” Can Help You Sell Off Surplus Inventory

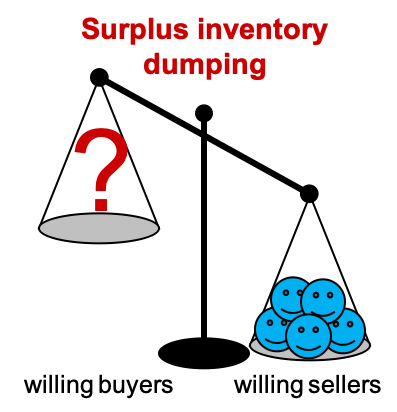

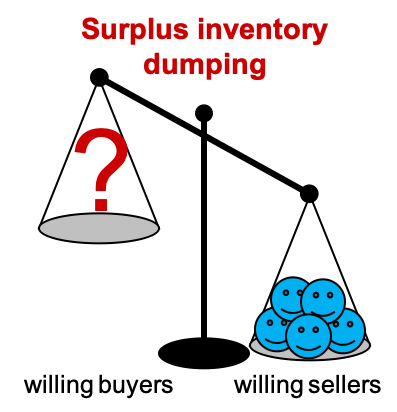

An active “inventory-sharing” network provides an audience of buyers (i.e., peer wholesaler-distributors) eager to provide faster product delivery to their end-customers. If the audience is sufficiently large and active, and if there is enough sourcing pain inflicted by one or more single-source suppliers common to network members, “inventory-sharing” can be an effective way to convert some of your surplus inventory into cash. The greatest challenge in using "inventory-sharing" as a method to sell off surplus inventory is attracting enough willing buyers to the network.

Best Practices for Selling Surplus Inventory in an “Inventory-Sharing” Network

If you are serious about leveraging a network of peer wholesaler-distributors as a solution for your surplus inventory problem, follow these guidelines:

If you are serious about leveraging a network of peer wholesaler-distributors as a solution for your surplus inventory problem, follow these guidelines:

- Offer to the network your active, high-velocity items too. Contributing to a department-store-variety of items in an “inventory-sharing” network will entice potential buyers to keep returning to the network, increasing the probability of someone finding your surplus items. Afraid to stock-out of an active, high-velocity item? Control its desirability via offer price. But still offer it to the network.

- Include a sell price in your data upload the network inventory database, up front. Potential buyers likely are browsing the network database while on the phone with their end-customers. They are not going to hang up, call you for a price and then call the end-customer back. Instead, they will see an offer price in the network database, mark it up and quote the end-customer during the initial phone call.

- Price your surplus items below current “best” wholesaler-distributor cost. It is better to recover some of the item’s original acquisition cost than to miss an opportunity for a sale because of price.

- Populate the network’s inventory data base using the single source’s (i.e., manufacturer’s) exact part number. No one outside your building knows your internal part numbers.

- Focus on branded, single-source items. Forget about trying to move surplus commodities via “inventory-sharing”.

- Be proactive in driving peer wholesaler-distributors to participate in your network. Help drive the network to “critical mass” participation. The fastest way to do this is to get your manufacturers to support/endorse “inventory-sharing” among the members of their wholesale channels.

- Be an active buyer in an “inventory-sharing” network. If you are not a frequent browser of the inventories owned by peer wholesaler-distributors, how can you expect them to be eager to browse your surplus inventory?

What Else Is Your Company Doing to Get Rid of Surplus Inventory?

Getting rid of surplus is actually very easy: just throw it away. Recovering your investment in surplus inventory is much harder. Personal experience suggests that a focus by dedicated resources working on multiple initiatives is essential for measurable results. Offering your surplus inventory to peer wholesaler-distributors via “inventory-sharing” is merely one initiative. It is a passive initiative in that you must wait for demand to find your surplus item. And it is not a panacea. What other, more proactive initiatives is your company working on to reduce your surplus inventory? Click here for suggestions.

Getting rid of surplus is actually very easy: just throw it away. Recovering your investment in surplus inventory is much harder. Personal experience suggests that a focus by dedicated resources working on multiple initiatives is essential for measurable results. Offering your surplus inventory to peer wholesaler-distributors via “inventory-sharing” is merely one initiative. It is a passive initiative in that you must wait for demand to find your surplus item. And it is not a panacea. What other, more proactive initiatives is your company working on to reduce your surplus inventory? Click here for suggestions.

About the Author

After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

About WarehouseTWO

WarehouseTWO, LLC is an independent “inventory-sharing” service created exclusively for durable goods manufacturers and their authorized distributors, and for any group of durable goods “peer” wholesaler-distributors, such as members of a buying/marketing group or cooperative. To learn how inventory-sharing with WarehouseTWO can help your business, visit the WarehouseTWO website, or email info@warehousetwo.com.

.png) Imagine exponentially increasing the amount and variety of inventory available to your end-customers without increasing the breadth or depth of your own inventory. By pooling each other’s finished goods into one big “virtual” pile of inventory, networks of peer wholesaler-distributors have a much better chance of meeting end-customers’ expectations of 1-to-2 day availability on anything. The practice of formal inventory collaboration among peer wholesaler-distributors is commonly referred to as “inventory-sharing”.

Imagine exponentially increasing the amount and variety of inventory available to your end-customers without increasing the breadth or depth of your own inventory. By pooling each other’s finished goods into one big “virtual” pile of inventory, networks of peer wholesaler-distributors have a much better chance of meeting end-customers’ expectations of 1-to-2 day availability on anything. The practice of formal inventory collaboration among peer wholesaler-distributors is commonly referred to as “inventory-sharing”. In our thirteen years of facilitating “inventory-sharing” networks, we at WarehouseTWO have learned that successful ones have these five attributes in common:

In our thirteen years of facilitating “inventory-sharing” networks, we at WarehouseTWO have learned that successful ones have these five attributes in common: How “Inventory-Sharing” Can Help You Sell Off Surplus Inventory

How “Inventory-Sharing” Can Help You Sell Off Surplus Inventory If you are serious about leveraging a network of peer wholesaler-distributors as a solution for your surplus inventory problem, follow these guidelines:

If you are serious about leveraging a network of peer wholesaler-distributors as a solution for your surplus inventory problem, follow these guidelines: Getting rid of surplus is actually very easy: just throw it away. Recovering your investment in surplus inventory is much harder. Personal experience suggests that a focus by dedicated resources working on multiple initiatives is essential for measurable results. Offering your surplus inventory to peer wholesaler-distributors via “inventory-sharing” is merely one initiative. It is a passive initiative in that you must wait for demand to find your surplus item. And it is not a panacea. What other, more proactive initiatives is your company working on to reduce your surplus inventory? Click here for suggestions.

Getting rid of surplus is actually very easy: just throw it away. Recovering your investment in surplus inventory is much harder. Personal experience suggests that a focus by dedicated resources working on multiple initiatives is essential for measurable results. Offering your surplus inventory to peer wholesaler-distributors via “inventory-sharing” is merely one initiative. It is a passive initiative in that you must wait for demand to find your surplus item. And it is not a panacea. What other, more proactive initiatives is your company working on to reduce your surplus inventory? Click here for suggestions. After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.