Categories: Inventory Management, Management

By Mark Tomalonis

Principal, WarehouseTWO, LLC

Have you ever stocked an item to support high volume sales to a single customer, only to end up owning some of that item long after the customer stopped buying it?

Have you ever stocked an item to support high volume sales to a single customer, only to end up owning some of that item long after the customer stopped buying it?

The onset of high-volume sales of one-customer items is like the beginning of a wonderful party: your customer and you are happy, sober... and rational. But like all good parties, high-volume sales of one-customer items eventually end, often with a mess, including surplus inventory for which the customer takes no responsibility. Such an outcome is avoidable if you plan ahead, at the beginning of the sales “party”. Avoid getting stuck with unwanted inventory with an “End of the Party” agreement.

Good inventory management is all about finding a balance between not owning enough inventory and owning too much inventory. For a high volume item sold primarily to one customer, “net stock” (“on hand” plus “on open purchase order” minus “allocated” minus “backordered”) should be equal to expected consumption during the item’s lead time plus a minimum “safety stock” quantity (for long lead time items, consider a two week supply as a “safety stock” quantity). This “net stock” quantity should be used as the “Limits of Liability” quantity in your “End of the Party” agreement, per section II below. Replenishment purchase orders should be placed every week, but only if replenishment quantities are needed. For more tips on how to manage inventory for a high volume OEM customer, read our article, “How to Work with a Customer-Provided Forecast”.

An “End of the Party” agreement should be either part of a pricing/supply agreement between you and your customer, or a separate contract between you and your customer. Typically, an effective “End of the Party” agreement includes these elements:

Opening Clauses: Include the customer’s company name, your company name and the time period for which this agreement is in effect. Reference any other contract or agreement applicable to this agreement.

List of Items: Include only those items for which most (e.g., at least 75%) of all sales is to this customer. (The shorter the list of items, the more likely the customer will accept the agreement.)

Limits of Liability: Include a quantity and value (in customer’s purchase price!) for each item for which the customer has potential liability. The quantity should consider forecasted or historical usage, the item’s lead time and a “safety stock” quantity. Refer to section I above, “How Much Inventory Should You Own for This Customer?”, for a suggested quantity. Define a method by which the customer can “buy out” its liability, such as purchasing a pre-defined quantity and then removing the item from the agreement.

The “Trigger”: Define the conditions under which the customer is required to purchase up to the liability quantity as defined in the section above. This part of the agreement is explained in greater detail, with examples, in section III below.

The “Outcome”: Define the action for which the customer is liable, should the “trigger” occur. This part of the agreement is explained in greater detail, with examples, in section IV below.

Signature Area: This agreement should be signed by a representative of the company who is authorized to make such a commitment on behalf of his/her company. The higher this person is in the customer’s management structure, the better.

...is a set of circumstances that, if not addressed, will result in you owning surplus inventory that you had purchased, speculatively, to support the customer’s needs.

“Trigger” Examples for an MRO Customer

Example A: Over a specified period, less than a threshold quantity is consumed: “During any three month period, you purchase less than half of the ‘limits of liability’ quantity.”

Example B: Over a specified period, none of the item is consumed: “During any six month period, you do not purchase any of this item.”

“Trigger” Examples for an OEM Customer

Example C: Over a specified period (e.g., item lead time plus two weeks), the actual consumption falls below a specified percentage of forecasted consumption during that same period: “Actual consumption during any six week period is less than fifty percent of forecasted consumption during that period.”

Example D: For a specified forecast period length (e.g., item lead time plus two weeks), actual consumption is less than forecasted consumption during a period equal to a specified multiple of the forecast period length: “Forecasted consumption during any six week period is not consumed within twelve weeks of the start of that six week forecast period.”

...defines the action that the customer must take to reduce or eliminate your liability of owning surplus inventory.

“Outcome” Examples for an MRO Customer

For “Trigger” Example A: Customer is obligated to purchase the ‘limits of liability’ quantity, less whatever quantity has been consumed since the beginning of the specified period: “You must purchase the ten units that I have been holding for you, less what you have already consumed in the last three months. We can then re-negotiate a new ‘limits of liability’ quantity, or remove this item from our agreement.”

For “Trigger Example B: Customer is obligated to purchase the ‘limits of liability’ quantity: You must purchase the then units that I have been holding for you, but you never purchased. We can then re-negotiate a new ‘limits of liability’ quantity, or remove this item from our agreement.”

“Outcome” Examples for an OEM Customer

For “Trigger” Example C: Customer is obligated to purchase the forecasted consumption quantity, less whatever quantity has been consumed since the beginning of the specified forecast period: “You must purchase what was forecasted during the six-week forecast period, less what you have already consumed since the beginning of this forecast period. We can then re-negotiate a new ‘limits of liability’ quantity, or remove this item from our agreement.”

For “Trigger Example D: Customer is obligated to purchase the forecasted consumption quantity, less whatever quantity has been consumed since the beginning of the specified forecast period: “You must purchase what was forecasted during the six-week forecast period, less what you have already consumed since the beginning of this forecast period, twelve weeks ago. We can then re-negotiate a new ‘limits of liability’ quantity, or remove this item from our agreement.”

The best time to negotiate an “End of the Party” inventory resolution commitment from your customer is during final discussions of whatever pricing agreement or contract you are about to accept, BEFORE you ship any product under that agreement/contract. This is the “beginning of the party”, when the customer is in his/her most favorable mood. After all, he/she has likely won pricing concessions from you, and he/she probably is happy with his/her selection of you as a preferred supplier. Also at this time, the customer cannot imagine that his/her forecast could be inaccurate, or that his/her business would change so much that the demand for your items would dry up abruptly.

The best time to negotiate an “End of the Party” inventory resolution commitment from your customer is during final discussions of whatever pricing agreement or contract you are about to accept, BEFORE you ship any product under that agreement/contract. This is the “beginning of the party”, when the customer is in his/her most favorable mood. After all, he/she has likely won pricing concessions from you, and he/she probably is happy with his/her selection of you as a preferred supplier. Also at this time, the customer cannot imagine that his/her forecast could be inaccurate, or that his/her business would change so much that the demand for your items would dry up abruptly.

Of course, forecasts ARE inaccurate, and demand for items DO dry up abruptly. This is WHY you should negotiate an “End of the Party” agreement.

While the customer is basking in the pending success of his/her negotiations with you (e.g, pricing and availability commitments by you), bring up the topic of unused inventory. Create and submit a draft of an “End of the Party” agreement, as defined in section II above. Suggested opening statements to your negotiation:

For an OEM Customer

“I am offering you these items at very favorable prices, and I will invest in inventory to meet your ‘just in time’ needs. You are my only customer for these items. To provide this level of support at these prices, I cannot afford to hold the inventory for very long, let alone get stuck with any of it permanently. I know that you will not commit to guaranteed consumption, and that I must manage to your forecast. Let us agree on a set of circumstances under which your forecast was unreasonable (the ‘trigger’) and what a fair resolution should be (the ‘outcome’).”

For an MRO Customer

“I am offering you these items at very favorable prices, and I will invest in inventory to meet your ‘just in time’ needs. You are my only customer for these items. To provide this level of support at these prices, I cannot afford to hold the inventory for very long, let alone get stuck with any of it permanently. I know that you will not commit to guaranteed consumption. Let us agree on a set of circumstances under which my business has been put in jeopardy (the ‘trigger’) and what a fair resolution should be (the ‘outcome’).”

Identifying the “trigger” in a timely manner is critical to negotiating an acceptable “outcome”. Not only will timely identification help you avoid purchasing more unwanted inventory, but it will help your credibility when negotiating the “outcome” with your customer. Consider these “trigger” identification methods:

For an MRO Customer

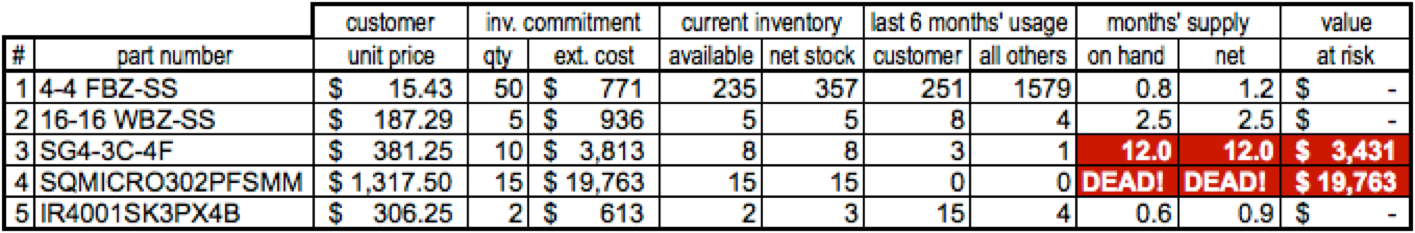

Using MS Excel and data available in your ERP (“enterprise resource planning”) system, create an analysis tool that shows all usage of the items listed in the agreement during a selected trailing period. Include usage by the target customer and usage by all other customers. Compare total usage by all customers to the “limits” of liability quantity (i.e, the quantity you committed to have in stock). Identify those instances where your inventory exceeds a selected number of months’ average usage. Figure 1 shows an example of such an analysis tool. In this example, the quantities owned of items #3 and #4 exceed six months’ usage. Update and review this information every month.

For an OEM Customer

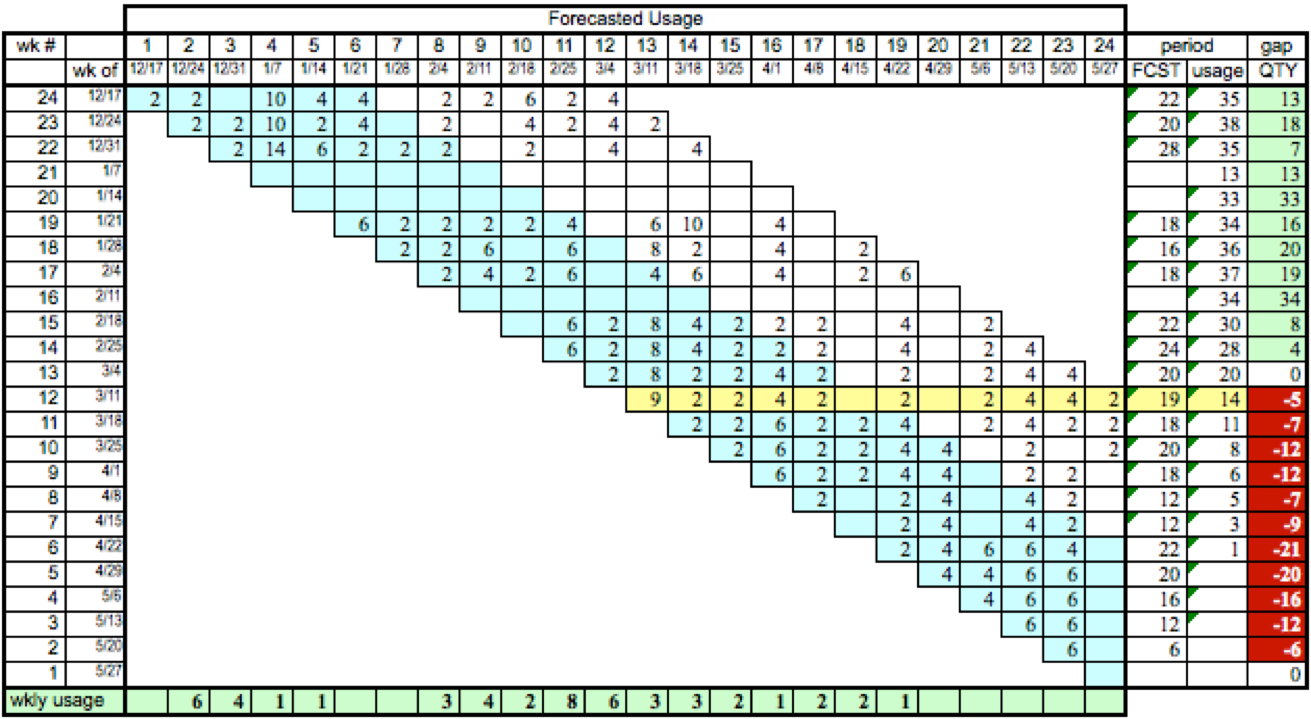

Analysis of an OEM’s consumption in comparison to its forecasted consumption can be a complicated endeavor. Weekly, not monthly, analysis is recommended. For each item listed in the agreement, combine historical forecast data with actual consumption data into an Excel worksheet. Such an analysis table might look like the example shown in Figure 2 below. This example is appropriate for an item with an average lead time of four weeks and a “safety stock” of two weeks’ forecasted usage. In this case, your total exposure should be equal to the next six weeks’ forecasted demand (quantities shown in blue-shaded cells). The worksheet captures weekly twelve-week forecasted consumption quantities along with actual consumption during the most recent twenty-four weeks. Cells in the “gap” column (last column) turn red if the actual quantity consumed in the most recent twelve week period is less than what was forecasted for the first six weeks of that forecast period. Action is “triggered” when the “gap” value is negative in the row representing the most recent twelve week period, identified here with yellow cells. In this example, representing data available through the end of the week of May 27, 2013, the customer purchased fourteen (14) units during the twelve week period starting on March 11, 2013, while the six week forecast starting on March 11, 2013, was nineteen (19) units. Therefore, a “trigger” has occurred and the customer is liable to purchase five (5) units of the item immediately. (If you managed your inventory properly, you should own no more than five units at this time.)

When a “trigger” has been identified, first verify the accuracy of your metrics. Once you have confirmed that the “trigger” is valid, contact the customer to review the original “End of the Party” agreement, and negotiate a commitment from the customer to purchase unused inventory per the terms of the agreed-to “outcome”. Any customer with integrity will cooperate fully, in the spirit of “partnering” with its favored supplier (you!).

It’s not a perfect world. Life is unfair. Here are some possible challenges associated with enforcing an “End of the Party” agreement, and how to deal with them.

About the Author After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis is now principal of WarehouseTWO, LLC. He amuses himself by writing articles, such as this one, to help wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

About WarehouseTWO

WarehouseTWO, LLC is an independent “inventory-sharing” service created exclusively for durable goods manufacturers and their authorized distributors, and for any group of durable goods “peer” wholesaler-distributors, such as members of a buying/marketing group or cooperative. To learn how inventory-sharing with WarehouseTWO can help your business, visit the WarehouseTWO website, or email info@warehousetwo.com.