Categories: Customer Service, Inventory Management

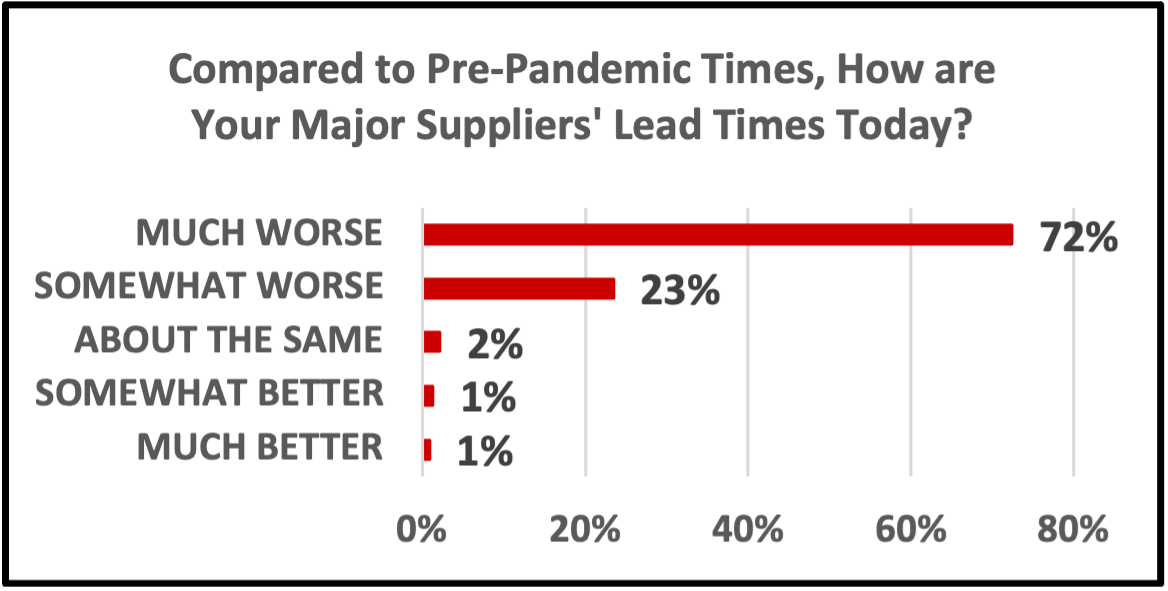

WarehouseTWO recently administered a poll to over 1,000 industrial distributors in North America with this one question: "Compared to pre-pandemic times, how are your major suppliers' lead times today?"

Here are their responses:

Granted, this was not a scientific poll. Still, it gives a strong indication that supply chains have not yet recovered back to pre-pandemic times.

If lead times from suppliers have changed this dramatically, what should you do about it? The best way to get through current supply chain challenges is to increase the efficiency of the finished goods inventory already sitting on your shelf and on peer distributors' shelves. That is, participate in "virtual inventory pooling". If all distributors who sell the same products can have access to each other's inventories, then available inventory can be redirected to meet the needs of end-customers among the distributor group. If you are a distributor participating in "virtual inventory pooling", the benefits to your company are:

For manufacturers, the benefits of "virtual inventory pooling" among its distributors has the powerful benefit of increasing factory floor efficiency: with manufacturing capacity struggling to meet demand, why set up manufacturing equipment to make something that already exists, sitting on a distributor's shelf, perhaps gathering dust?

Two things about "virtual inventory pooling" among a manufacturer's distributors that you should know:

Our lead time poll makes it clear: supply chains are performing much worse than they were pre-pandemic. This change warrants a change in how you get product to your end-customers. If not via "virtual inventory pooling", how is your company dealing with longer lead times?

Got a question or comment about this article? Email me.

About the Author After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis created the inventory-pooling software system that is now WTWO, LLC, dba WarehouseTWO. He amuses himself by writing articles, such as this one, to help manufacturers and wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

After a successful career in sales and operations management in the wholesale-distribution industry, Mark Tomalonis created the inventory-pooling software system that is now WTWO, LLC, dba WarehouseTWO. He amuses himself by writing articles, such as this one, to help manufacturers and wholesaler-distributors execute their operations better. Mark’s articles and tips are published in WarehouseTWO’s monthly e-newsletters. Click here to subscribe.

About WarehouseTWO

WarehouseTWO is an independent “inventory-pooling” service created exclusively for durable goods manufacturers and their authorized distributors, and for any group of durable goods “peer” wholesaler-distributors, such as members of a buying/marketing group or cooperative. To learn how inventory-pooling with WarehouseTWO can help your business, visit the WarehouseTWO website, or email info@warehousetwo.com.